Böhler Welding equipment for increased productivity

For what concerns the MIG-MAG process, the challenges in the world of welding are increasingly related to enhancing productivity in combination with high quality and flexibility. In this respect, both the performance of the electric arc that determines welding speed and deposition rate, as well as the efficiency in setting up the machine and its ease of use, are also crucial.

The quality aspects in terms of chemical-mechanical properties, integrity, and aesthetics of the joints, as well as the repeatability of the process, are equally crucial to meet the imposed requirements. In addition, the quality of the welded joint has an impact on productivity with regard to oxide and silicate cleaning operations, adjustment of any etching, and repair of unacceptable defects.

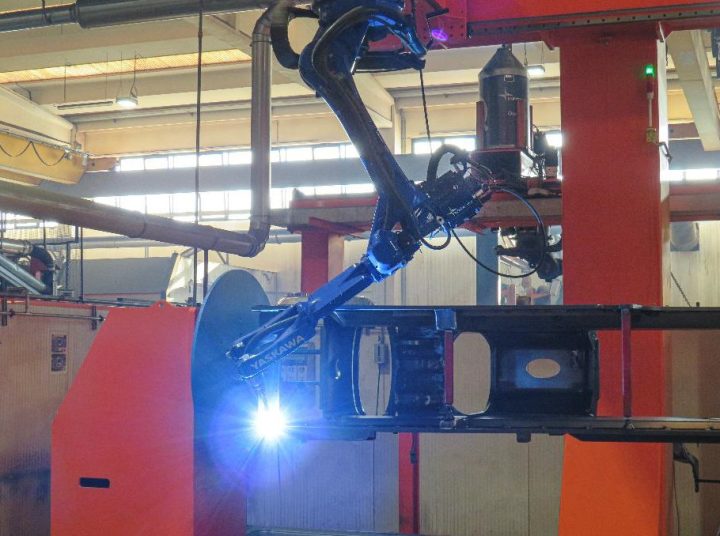

Thanks to special MIG-MAG processes and dedicated welding programs, the latest generation of Böhler Welding’s equipment meets the aforementioned increasing demand for enhanced productivity while also improving quality aspects.

This case study examines some applications in the area of high-strength unalloyed and low-alloyed steel structures, reporting objective evidence regarding the benefits obtained thanks to Böhler Welding solutions.

For more info, click HERE to download the PDF of the case study.